about us

Professional PCB & PCBA production

As a specialized LED PCB manufacturer, we deliver high-performance, energy-efficient circuit boards designed for superior brightness and durability. Whether for lighting, displays, or automotive applications, our precision-engineered LED PCBs ensure optimal thermal management and long-lasting performance.

Our advantages

Why Partner With Us?

✔ Thermal Excellence: Optimized metal-core designs for maximum heat dissipation.

✔ Precision & Quality: ISO-certified production with strict reliability testing.

✔ Custom Solutions: Tailored substrates for high-power LED, automotive, and industrial applications.

✔ Fast-Track Innovation: R&D support for next-gen lighting and electronic systems.

Driving Bright Ideas with Smarter PCBs – Your trusted partner for high-performance metal-core circuit boards.

Sample:24hours. And Mass production: 7 days

More than 100,000m² per month

Tailored substrates for high-power LED, automotive, and industrial applications.

ISO, ROSH, UL, SGS, IPC certified production with strict reliability testing.

PCB production process

Engineered for Excellence, Built for Performance

Your Vision, Our Circuit – Superior PCBs Made Simple

| Step | Process Stage | Description |

|---|---|---|

| 1 | Design and Output | Create PCB layout using EDA software and generate Gerber files |

| 2 | Print the Design | Print the circuit pattern onto a film |

| 3 | Inner Layer Imaging | Transfer the circuit image onto the inner copper layers using photoresist |

| 4 | Inner Layer Etching | Etch away excess copper, leaving behind the circuit pattern |

| 5 | Inner Layer AOI Inspection | Use Automated Optical Inspection to check for defects |

| 6 | Layer Lamination | Press all layers together to form a multilayer board |

| 7 | Drilling | Drill holes for vias, through-holes, and mounting |

| 8 | Plating (Electroless Copper) | Deposit a thin layer of copper inside the holes |

| 9 | Outer Layer Imaging | Transfer circuit image onto outer layers |

| 10 | Outer Layer Etching | Remove unwanted copper on outer layers |

| 11 | Outer Layer AOI Inspection | Inspect outer layers for accuracy and defects |

| 12 | Solder Mask Application | Apply solder mask to protect circuits and prevent short circuits |

| 13 | Surface Finish (e.g., HASL, ENIG) | Apply surface treatment to enhance solderability |

| 14 | Silkscreen Printing | Print labels, logos, and part identifiers on the PCB surface |

| 15 | Routing / V-Scoring | Cut the board into individual units or add break lines |

| 16 | Final Inspection & Electrical Test | Perform visual and electrical testing to ensure functionality |

| 17 | Packaging and Shipping | Pack finished boards and prepare for delivery |

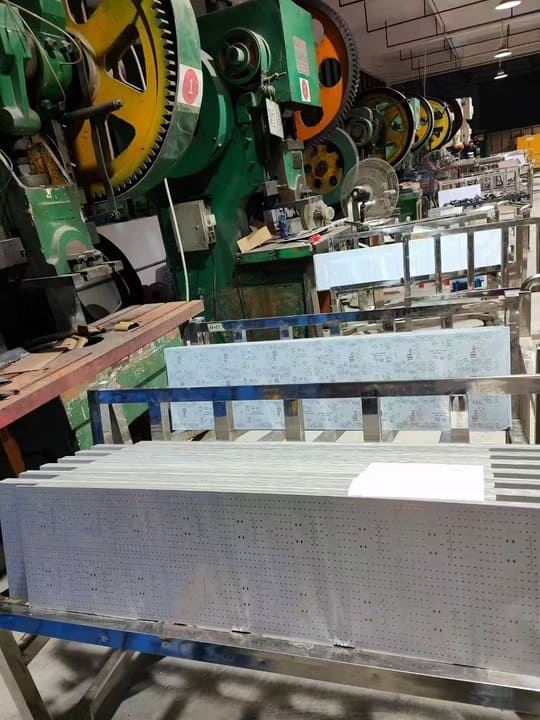

Our Factory

Experience

Expert LED PCB Manufacturing – Brighten Your Innovations

Our automated lines have increased production capacity by 30% while maintaining precision.